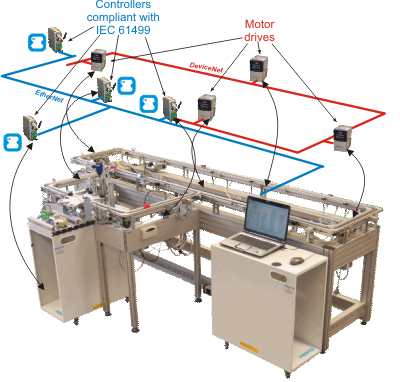

The laboratory is

equipped with a range of intelligent mechatronic models forming a model

of a reconfigurable manufacturing environment, also known as Intelligent

Mechatronic Testbed.

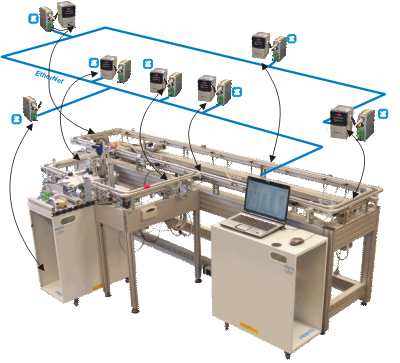

Sample architecture 1: EtherNet connected IEC-61499 compliant controllers with DeviceNet links to drives. Some controllers are one per conveyor section, some serve several sections, but all sections have their own software (function block).

Two conveyors together form the diverting loop. In the gap between conveyors one or two processing stations can be inserted without any change to the control code.

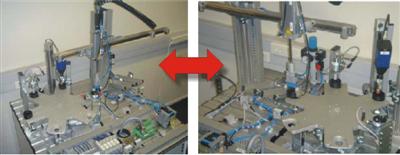

Distributed control enables trading places of two stations “on the fly. This and other physical reconfigurations have been achieved without changing the code in embedded controllers.

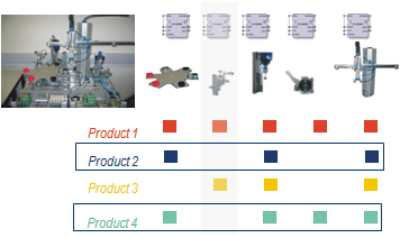

Producing different products on the same line: distributed control adapts to the availability of mechatronic actors.

The line can keep producing some products even a machine or two are out of order. No control change is required.

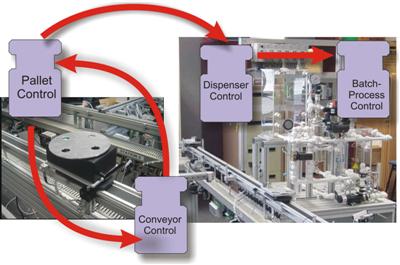

Batch processing plant model with distributed control produces some liquid product and dispenses it to the vessels on the vehicle. The vehicle is modelled by the Smart Pallet with rotating table and wireless controller.

There are several control nodes interacting as follows: